Voestalpine’s Innovative Approach to Sustainable Steel Production

In a significant move towards sustainability and innovation within the steel production industry, voestalpine has joined forces with Mercedes-Benz and TSR Recycling to launch an ambitious project designed to transform the way we think about steel production and the circular economy. This pioneering project is set to demonstrate the feasibility of recycling post-consumer scrap – commonly referred to as “old scrap” – into high-quality scrap that is then processed to produce premium-grade steel. This high-grade steel will ultimately find its application in the automotive industry, marking a major advancement in sustainable manufacturing practices.

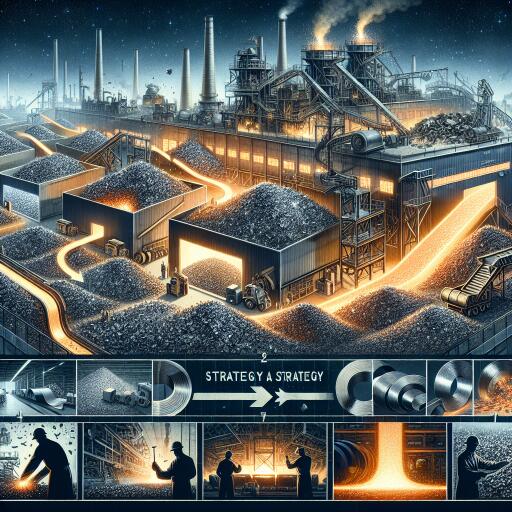

This groundbreaking initiative is part of voestalpine’s greentec steel initiative, which aims to significantly alter its production methods by replacing traditional blast furnaces with electric arc furnaces (EAF) in its Linz and Donawitz plants starting in 2027. These electric arc furnaces will utilize a mixture of liquid pig iron, briquetted sponge iron (HBI), and scrap, tailored to meet specific quality standards. The emphasis on scrap as a primary raw material underscores its vital role in the move towards green steel production.

Herbert Eibensteiner, CEO of voestalpine AG, expressed optimism about the project, stating that voestalpine has a long history of closing production loops to conserve resources and secure a reliable supply of raw materials. He underlined the importance of the partnership with Mercedes-Benz and TSR Recycling as an opportunity to further the company’s commitment to the circular economy and to pave the way for green steel production.

Hubert Zajicek, a member of the voestalpine AG Management Board and the head of the Steel Division, pointed to the technological challenge of producing premium steel grades through low-emission methods as part of the transition towards sustainable steel manufacturing. He revealed that the company is actively researching various processes and collaborating with partners to tackle these challenges, ensuring that voestalpine remains at the forefront of producing high-quality steel grades amid technological evolution.

The inherent recyclability of steel allows it to be reused repeatedly with negligible quality loss, positioning high-quality pre-consumer scrap or “new scrap” as a cornerstone of modern steel production. However, the shift towards green steel production in the European industry has led to an increased demand for recycled material that cannot be met by new scrap alone. This gap highlights the future importance of old scrap, which requires more elaborate processing and sorting to match the purity levels of new scrap, for the production of premium-grade steel.

In this high-stakes collaboration, voestalpine, Mercedes-Benz, and TSR are working together to reprocess less pure post-consumer scrap into top-grade steel. An exemplar of this effort is the utilization of the reprocessed steel as side panels in the Mercedes A-Class sedan, showcasing the potential for old scrap to be transformed into valuable components for the automotive industry.

This venture not only emphasizes the importance of innovation in recycling processes and the utility of circular economy principles but also sets a new benchmark for sustainability in the steel production industry. By turning old scrap into high-quality steel, voestalpine and its partners are leading by example, demonstrating the significant environmental and economic benefits of embracing a sustainable approach to material sourcing and manufacturing.

The voestalpine initiative shines a light on the future of steel production, where sustainability, innovation, and collaboration converge to create eco-friendly solutions that meet the demands of modern manufacturing and environmental stewardship. This project serves as a beacon of hope for industries worldwide, proving that through dedication and partnership, it is possible to make significant strides in the pursuit of green and sustainable production methodologies.